Back to Basics: Explaining Centrifugal Fan Airflow

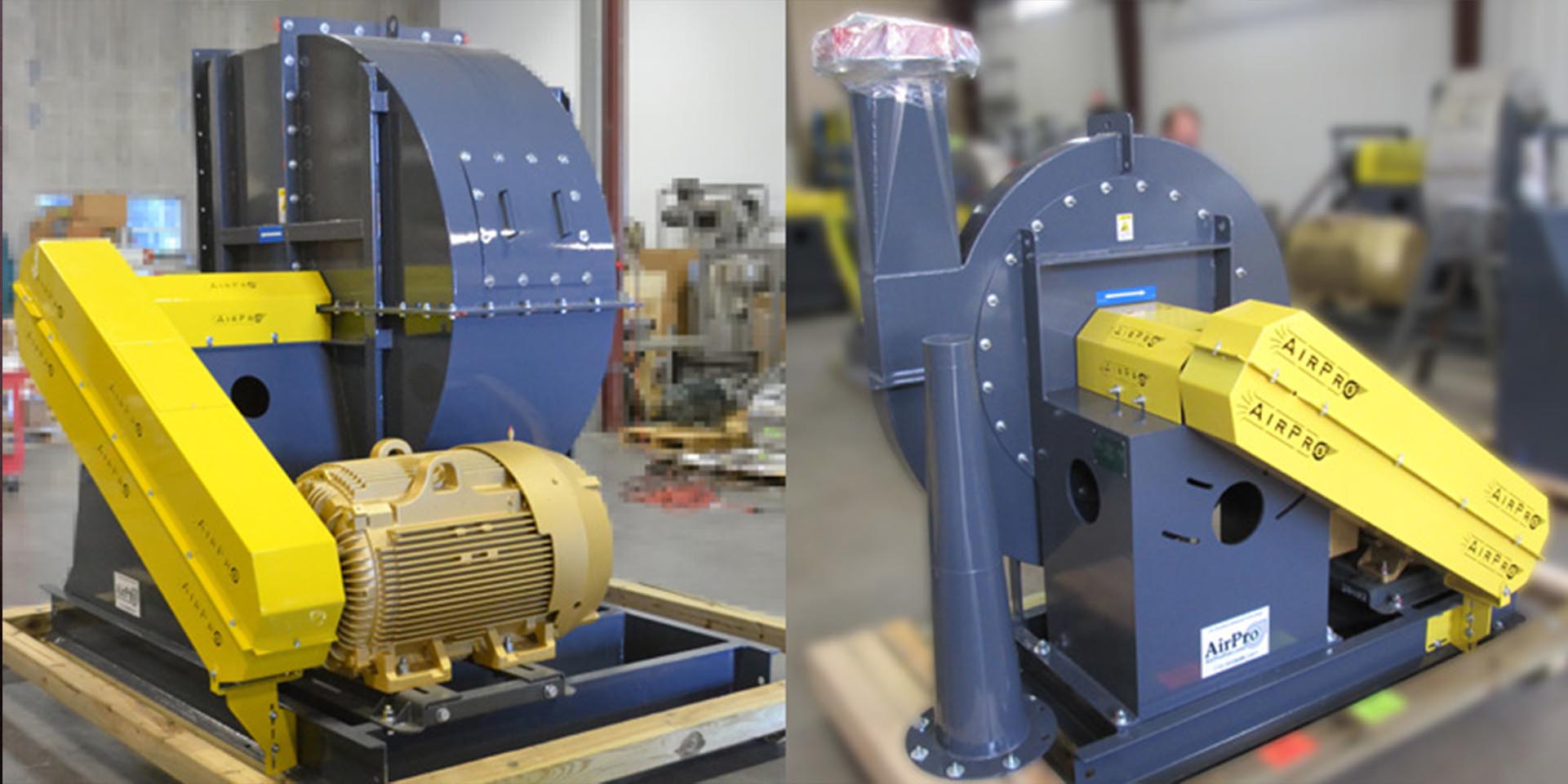

There’s more to a centrifugal fan than blade structure (versus axial) and function (to move process air and other materials as part of a larger system). Centrifugal fan airflow is at the core of how it works.