Updated Application Page on FD Fans

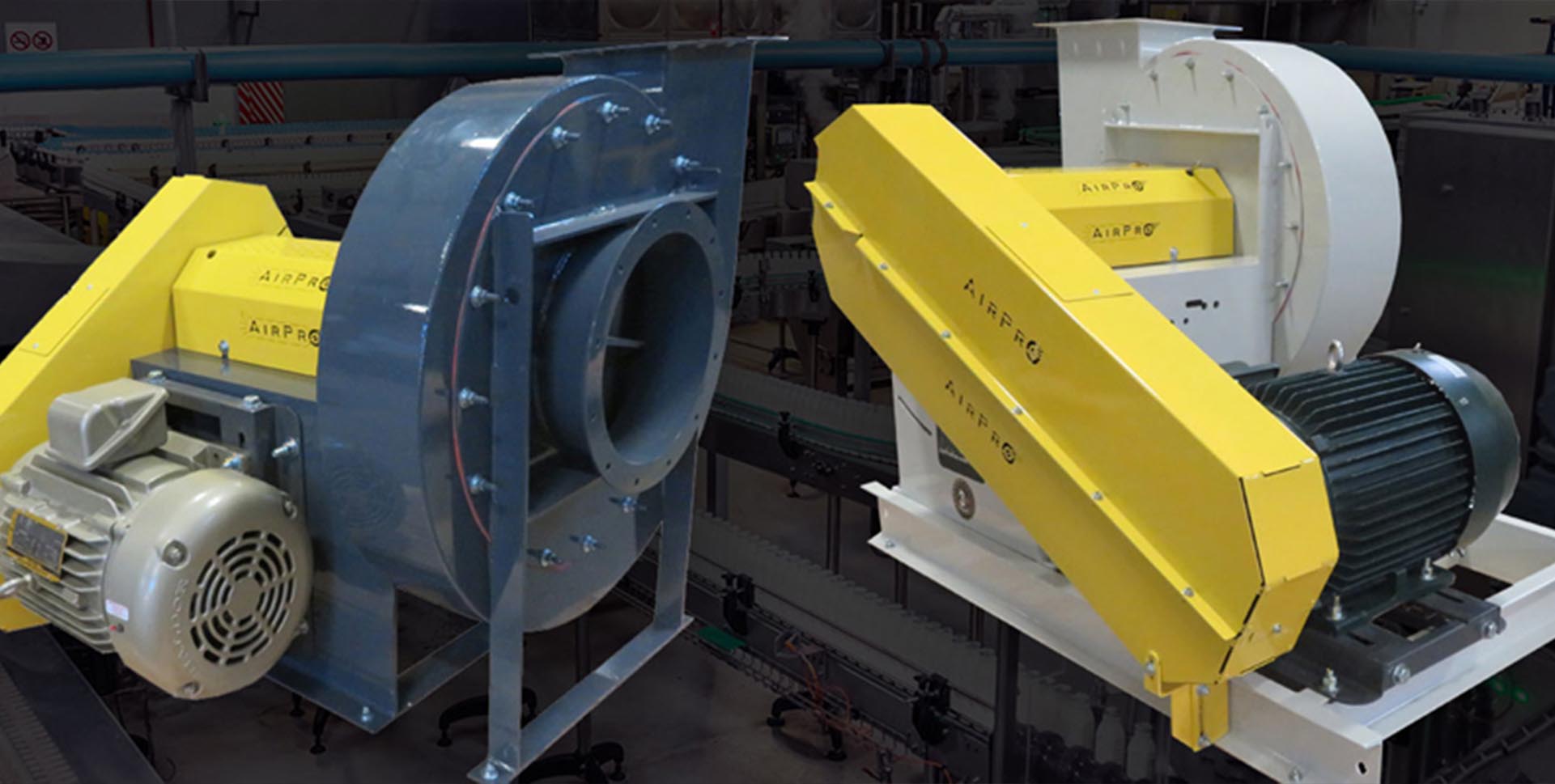

FD fans create positive air pressure and volume at the outlet to push air through the system. For reference, fans are either forced or induced draft. Induced draft fan (ID fan) applications focus pressure at the inlet. You can read more on ID fans here.