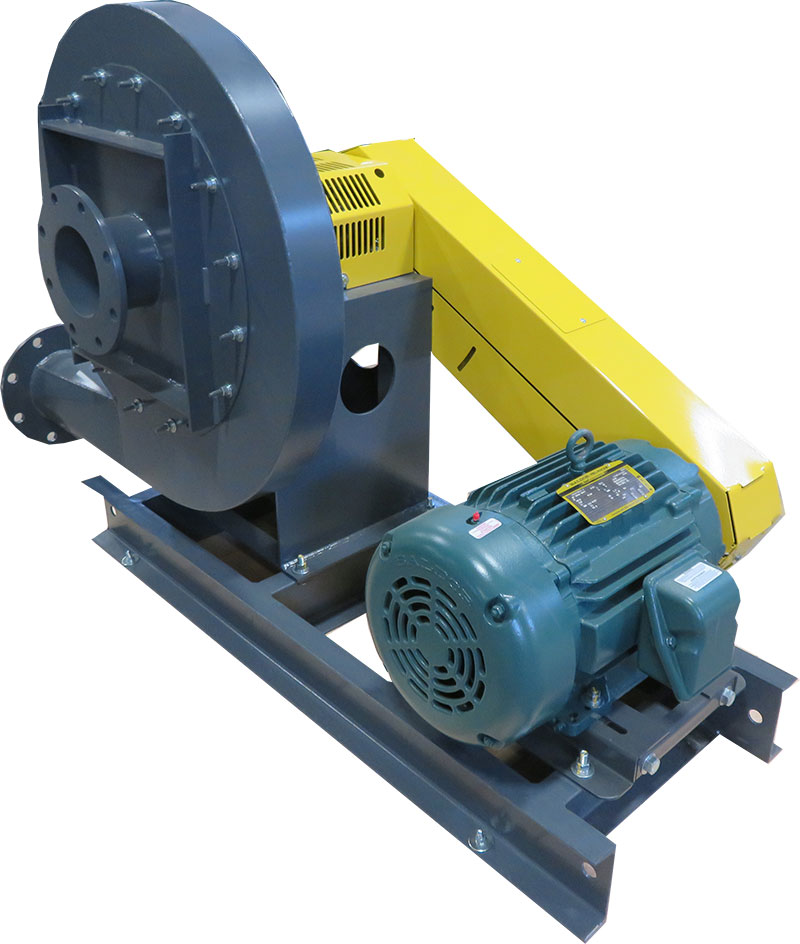

We provided these custom high-pressure SCR blowers (one primary with an identical redundant/backup blower) for this mission-critical Selective Catalytic Reduction (SCR) application. Designed for high-temperature operation at 800 degrees max design temperature with a tight 15-degree min/max rate of temperature change. The blowers have 15 HP IEEE841-rated premium-efficiency, severe-duty motors to meet the high standard required for operation in the petroleum and chemical industry.

SCR blowers provide pollution control for the NOx-laden flue gas produced as a by-product of petroleum and chemical manufacturing processes. The US Environmental Protection Agency (EPA) requires manufacturers to treat the flue gas to bring down NOx levels before releasing the exhaust into the atmosphere. The tight rules that govern industrial emissions drive the need for a redundant SCR blower as a backup. The plant cannot continue to operate without it. Learn more about SCR applications, pollution control, and high-pressure blowers.

Performance: 22,000 cfm airflow @ 26″ wg static pressure @ 0.07lb/ft^3 inlet air density

| Product Type | BCHX (backward curved) |

| Size | 451 (45.1” diameter wheel) |

| Class | 5 |

| Arrangement | 8 (direct-coupled drive) |

| Horsepower | 125 HP |

| Max Design Temperature | 150°F |

For more information, read about backward curved and induced draft fans.