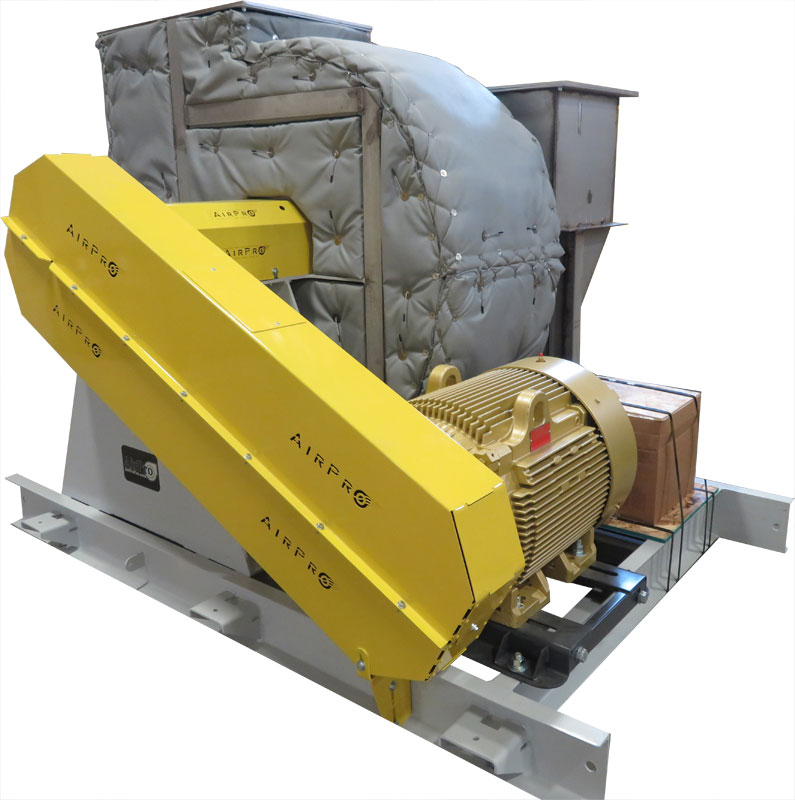

For this petrochemical plant application, we custom designed and delivered a backward curved exhaust fan, including a 304 Stainless Steel airstream, 3-inch sound insulation, spring vibration isolators, inlet and outlet flex connectors, and a unitary base.

This backward-curved model is spark-resistant and cost-efficient, built for medium air volume with static efficiencies above 80%. Because of where the fan is situated within the petrochemical application, this fan also required spring vibration isolators to protect the fan from excess vibration, and flex connectors (or expansion joints) to protect the surrounding ductwork from the movement of the fan during operation.

Petrochemical plants convert crude oil, natural gas, or other natural resources into products like ethylene and propylene. This process produces exhaust streams containing potentially hazardous chemical and gas residue, requiring corrosion-resistant materials of construction like 304 Stainless Steel in the fan airstream.

Performance: 23,000 acfm airflow @ 18” wg static pressure @ 0.05 lb/ft^3 inlet air density

| Product Type | BCMS (backward curved) |

| Size | 410 (41” diameter wheel) |

| Class | 5 |

| Arrangement | 1 (belt drive with unitary base) |

| Horsepower | 100 HP |

| Max Design Temperature | 220°F |

If you have a similar project, contact an application engineer to discuss it in more detail.