For many industrial fan customers, the key priority is getting the right amount of airflow at the right price without paying for unnecessary features. That was the case for a recent project where a customer in California needed a simple, reliable, and cost-effective solution to deliver ambient air into a Regenerative Thermal Oxidizer. Rather than an industrial-duty fan built for extreme environments, this application called for a practical, streamlined approach—one that AirPro was well-positioned to deliver with the P10C 275 pressure blower.

Application: RTO

Pressure Blower for a Combustion Burner on a Thermal Oxidizer

Introducing the P06A, a key component of our innovative P## series of pressure blowers. We are pleased to highlight this compact yet powerful blower, meticulously engineered for a combustion burner on a thermal oxidizer for a valued customer in Texas.

We designed a high-temperature purge fan for this regenerative thermal oxidizer (RTO) system application. The purge fan blade profile is backward curved to process high airflow at medium pressures. Customized to handle high temperatures, the application called for inlet and outlet expansion joints, and 2” thick insulated housing and inlet box, and an Arrangement 8 direct-coupled drive motor.

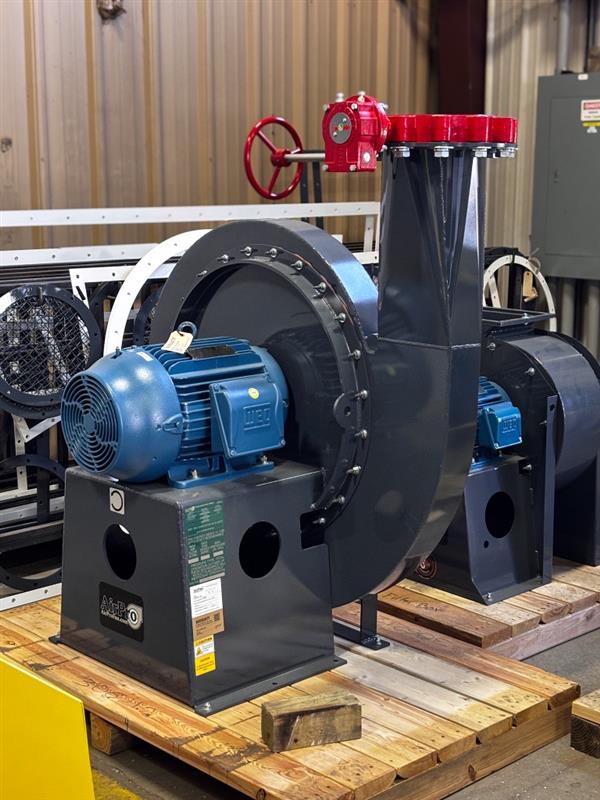

We provided a set of three fans for this thermal oxidizer application designed for pollution control at a copper purification, treatment, and manufacturing plant.

We recently designed and manufactured a custom induced draft fan for a Regenerative Thermal Oxidizer (RTO) application. The design featured our backward-curved technology with an Arrangement 8 configuration.

For this Regenerative Thermal Oxidizer (RTO) fan application, we custom designed and delivered a high-temperature backward-curved fan with thermal insulation, aluminum cladding, vibration sensors on the bearings, companion flanges, extended lubrication lines, and an inlet box.

Centrifugal Fan Applications for Thermal Oxidizer Manufacturers

Thermal Oxidizers (TO) and Regenerative Thermal Oxidizers (RTO’s) are essential industrial air pollution control equipment. Thermal Oxidizer manufacturers provide RTOs and TOs as OEMs for many industries that need to ensure safety, comfort, and compliance in their facilities as well as surrounding environments.

The following high pressure blowers, ordered through an AirPro OEM customer, were built for an oxidizer/scrubber system that destroys methane, chloride and fluoride compounds, and jet fuel.