At AirPro Fan & Blower Company, we believe that staying ahead means continuously investing in the tools and technology that allow us to serve our customers better. That’s why we’re excited to share how our recent implementation of three major technology initiatives is revolutionizing both our capabilities and our team’s professional growth.

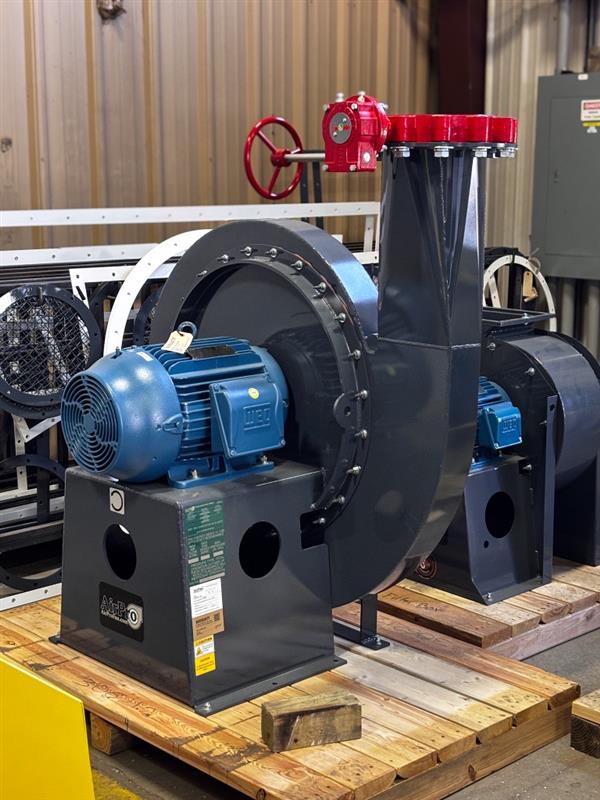

Going Beyond Manufacturing Exceptional Fans

Our commitment to our customers extends far beyond delivering exceptional fans. At AirPro, continuous improvement applies to every aspect of the customers’ experience with us. These technology investments allow us to provide faster turnaround times, more accurate diagnostics, and enhanced quality assurance that our customers can count on.

Advanced Material Analysis: Quality You Can Trust

We’ve implemented the Hitachi PMI Master Pro 2 Optical Emission Spectroscopy system, representing a significant leap forward in our quality control capabilities. This advanced material analyzer enables us to:

- Instantly verify material composition and quality for all incoming materials

- Provide customers with certified Positive Material Identification (PMI) reports when required

- Prevent costly material mix-ups that could compromise performance or safety

- Ensure customers receive full value for scrap materials through accurate identification

This technology allows us to catch potential material issues before they become customer problems. We can now guarantee that every fan we build uses exactly the materials specified, giving our customers complete confidence in their investment.

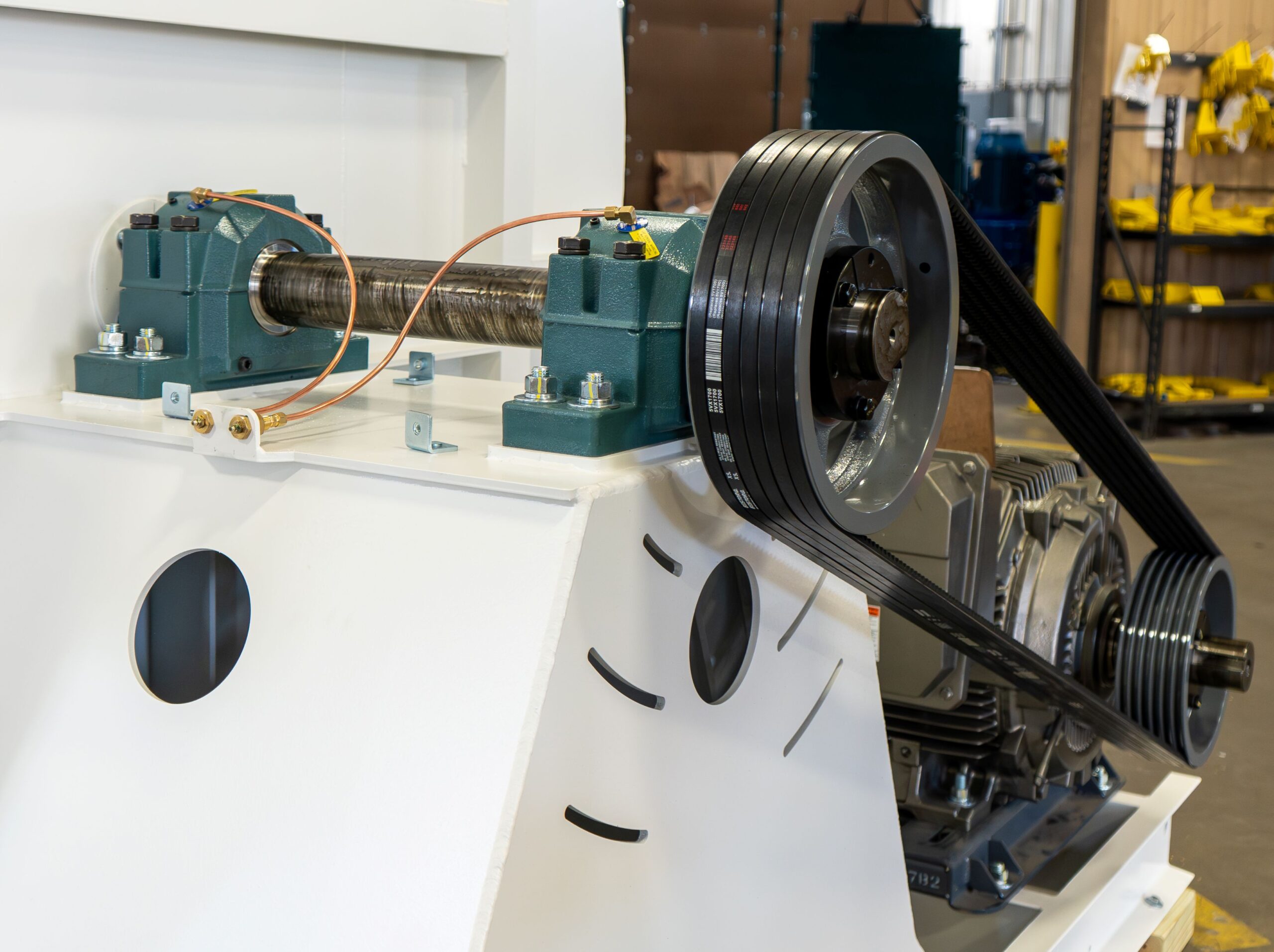

Revolutionary 3D Scanning: Accelerating Our Reverse Engineering Services

Our investment in FARO 3D scanning technology with PolyWorks software dramatically enhances our reverse engineering capabilities. This sophisticated system enables us to:

- Perform high-precision scanning of obsolete or damaged components

- Rapidly create detailed engineering drawings and 3D models

- Deliver faster turnaround times for customers needing replacement parts for legacy equipment

- Conduct enhanced quality inspection on manufactured components

This technology is particularly valuable for customers operating older equipment where original parts are no longer available. When a customer’s production depends on a fan component that’s no longer manufactured, we can now scan, analyze, and reproduce that part with incredible accuracy in a fraction of the time it used to take.

Collaborative Robot Technology: The Future of Manufacturing Excellence

Our successful deployment of a collaborative welding robot (cobot) represents our commitment to advanced manufacturing while maintaining the craftsmanship customers expect. Key benefits include:

- Consistent, high-quality welds that match traditional hand-welding precision

- Faster production times for repeat orders and standard configurations

- Enhanced safety through automation of repetitive welding tasks

- Improved capacity to handle larger orders without compromising quality

The robot doesn’t replace our skilled welders. It empowers them to focus on more complex, value-added work while ensuring consistent quality on high-volume runs.

Empowering Our Team’s Professional Growth

Beyond customer benefits, these technology investments provide our team members with valuable opportunities for professional development and skills advancement:

Advanced Technical Training: Our team members receive comprehensive training on sophisticated equipment operation, programming, and maintenance, adding valuable technical skills to their expertise.

Cross-Functional Learning: Engineers gain hands-on experience with manufacturing technology, while production team members develop programming and analytical skills typically associated with engineering roles.

Industry-Leading Experience: Exposure to cutting-edge technology keeps our employees at the forefront of manufacturing innovation, professional development, and job satisfaction.

We believe that investing in technology means investing in our people. Team members with well-developed skills and experience help us reach our speed and quality targets more efficiently.

Building on Our Foundation of Excellence

These technology investments build upon our established reputation for quality and service excellence. Our 36-month Gold Standard Warranty, ISO 9001:2015 certification, and comprehensive field service capabilities already set industry standards. These new technology platforms enhance our existing strengths while positioning us for continued growth and innovation.

Looking Forward

Our customers have always known they can count on AirPro for exceptional products and responsive service. These technology investments ensure we’ll continue exceeding their expectations while providing our team with the advanced tools they need to deliver that excellence.As we continue to grow and evolve, we remain committed to the principles that have guided us from the beginning: unmatched quality, reliable performance, and responsive service. Now, with these advanced capabilities, we’re better equipped than ever to deliver on that promise.