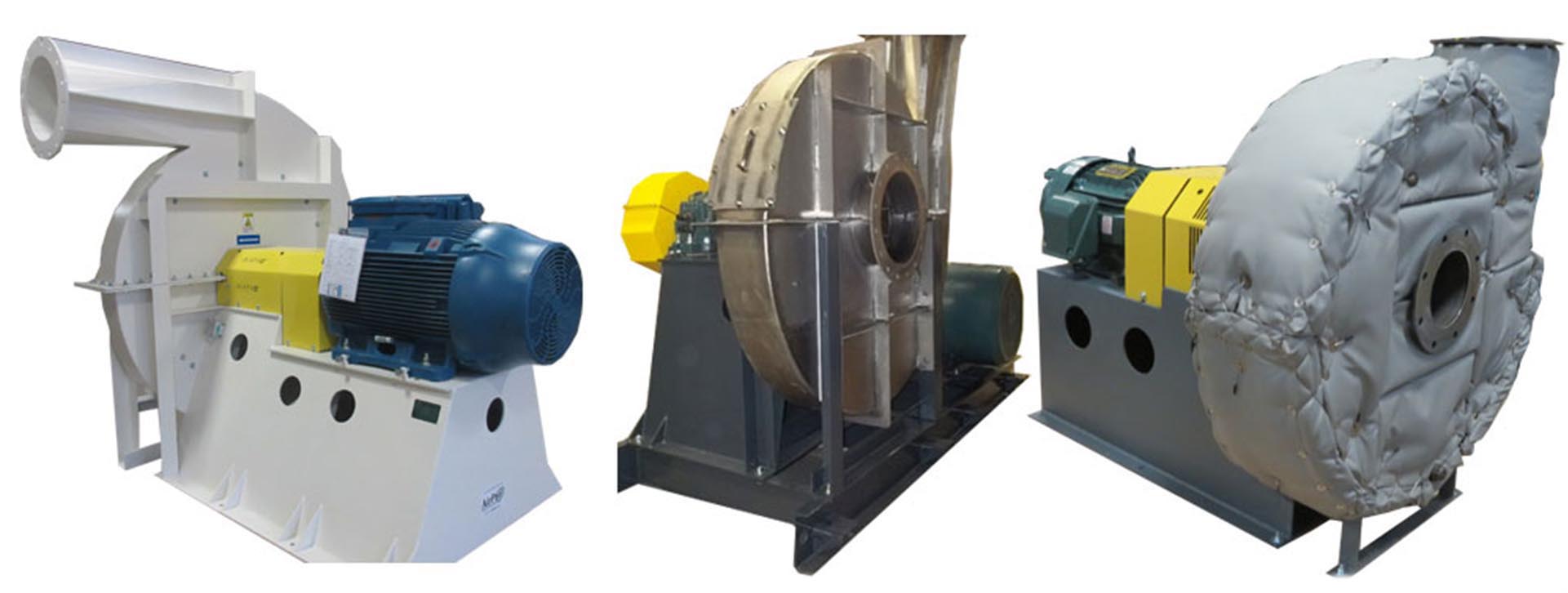

We provided these custom high-pressure SCR blowers (one primary with an identical redundant/backup blower) for this mission-critical Selective Catalytic Reduction (SCR) application. Designed for high-temperature operation at 800 degrees max design temperature with a tight 15-degree min/max rate of temperature change. The blowers have 15 HP IEEE841-rated premium-efficiency, severe-duty motors to meet the high standard required for operation in the petroleum and chemical industry.

High Pressure Blower

This installation is an example of a purge air system utilizing an AMCA Type “A” Spark Resistant Exhaust Blower. Designed for the OEM as part of the larger purge system to help prevent contamination of electrical surfaces from overheating, corrosive gasses, and dirt by moving clean air through the system. This high-pressure arrangement-1 blower features an aluminum fan wheel and housing for spark resistance.

Introducing a Custom High Pressure Blower Line Extension

Industries such as Petrochemical & Chemical often require extremely customized industrial blowers to meet industry standards with maximum reliability. If that’s you, we’ve got good news. We now offer an ultra-custom High Pressure Blower line with increased airflow capacity up to 150,000 cfm. Stringent customizations are available, including API 673/560 compliance. If that’s all you need to know, we’re ready to talk.

AirPro recently built Induced Draft Blowers for an overseas pharmaceutical dryer application. The fans were designed to pull over 100″ WGSP vacuum as they dry powder for final processing. AirPro performed a customer witnessed performance test to confirm actual results consistent with customer specifications.

The cement plant supervisor who ordered this high pressure blower contacted AirPro after attempting to obtain a quick shipment from multiple fan companies. The best expedite timeline he had been offered was 5 weeks. AirPro promised a 7 day expedite option and shipped the fan in 5 days.

AirPro recently built a couple of high pressure blowers for a US paper mill upgrading their power-generating boiler system from coal to biomass. The blowers are supplying the combustion air for the new burner system. Special attention had to be given to proper pressure and air flow as the blowers were required to be located a floor below the actual boiler due to space restrictions. AirPro supplied the fan skid complete with inlet filters/silencers and installed the damper/actuator system, designed and supplied by the plant manager/project engineer overseeing the project.

The following high pressure blowers, ordered through an AirPro OEM customer, were built for an oxidizer/scrubber system that destroys methane, chloride and fluoride compounds, and jet fuel.

Our customer requested an expedited delivery on Monday because they needed the fan ASAP. Sales promised a 5-day delivery. Engineering provided an accurate, customer-specific design. In two days Manufacturing built a rugged, industrial duty fan with custom dimensions. By Friday, 4 days following confirmation of expedited ship date, the fan had been balanced, painted, assembled, trimmed, and shipped.