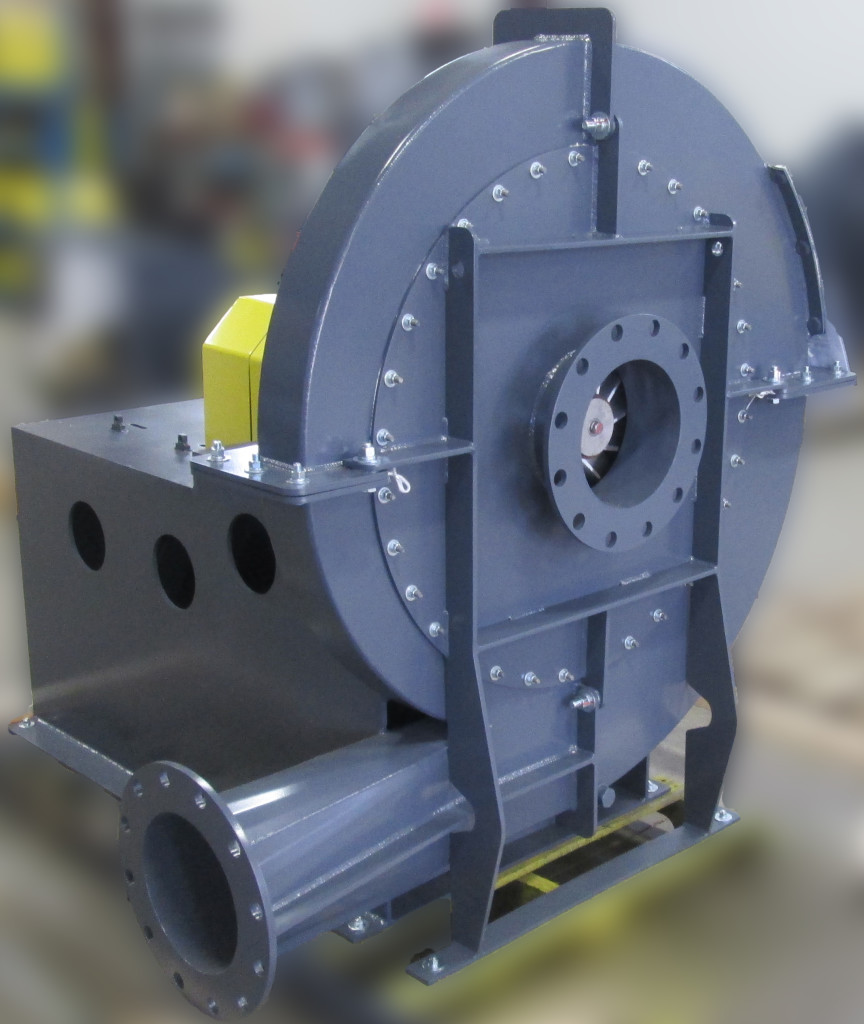

We provided these custom high-pressure SCR blowers (one primary with an identical redundant/backup blower) for this mission-critical Selective Catalytic Reduction (SCR) application. Designed for high-temperature operation at 800 degrees max design temperature with a tight 15-degree min/max rate of temperature change. The blowers have 15 HP IEEE841-rated premium-efficiency, severe-duty motors to meet the high standard required for operation in the petroleum and chemical industry.

Application: SCR

Centrifugal Fan Applications for SCR Systems

Power plants and other industrial operations that involve combustion often use Selective Catalytic Reduction (SCR) systems for pollution control and environmental compliance. SCR systems pull flue gas out of the gas stream and inject it with a reagent (usually Ammonia or Urea) to reduce Nitrogen Oxide (NOx ) levels before exhausting to the atmosphere. SCR systems are a critical part of meeting acceptable emissions levels put forth by the Environmental Protection Agency (EPA).

Backward Curved Models Now Offer Smaller Fan Sizes

We are excited to announce the expansion of our Backward Curved models to include fans with wheel diameters below 27 inches. Combustion Air and other Forced Draft applications often require fans designed for low airflows at higher pressures, and we have traditionally supplied our high-pressure blower models for these applications. But our customers started asking us for fans with lower horsepower requirements, and our product development team set out to expand our offerings with more efficient options.

Story: The following high temperature fan was built for a power company in Colorado. Several years ago, the customer had purchased a Selective Catalytic Reduction (SCR) system with fans provided by a competitor. What followed was a continuous string of unresolved bearing failures that resulted in unreliable performance and unacceptable maintenance costs. Finally, AirPro was called in to review the application and offer a solution.