Manufacturing Efficiency & Growth in the Time of COVID

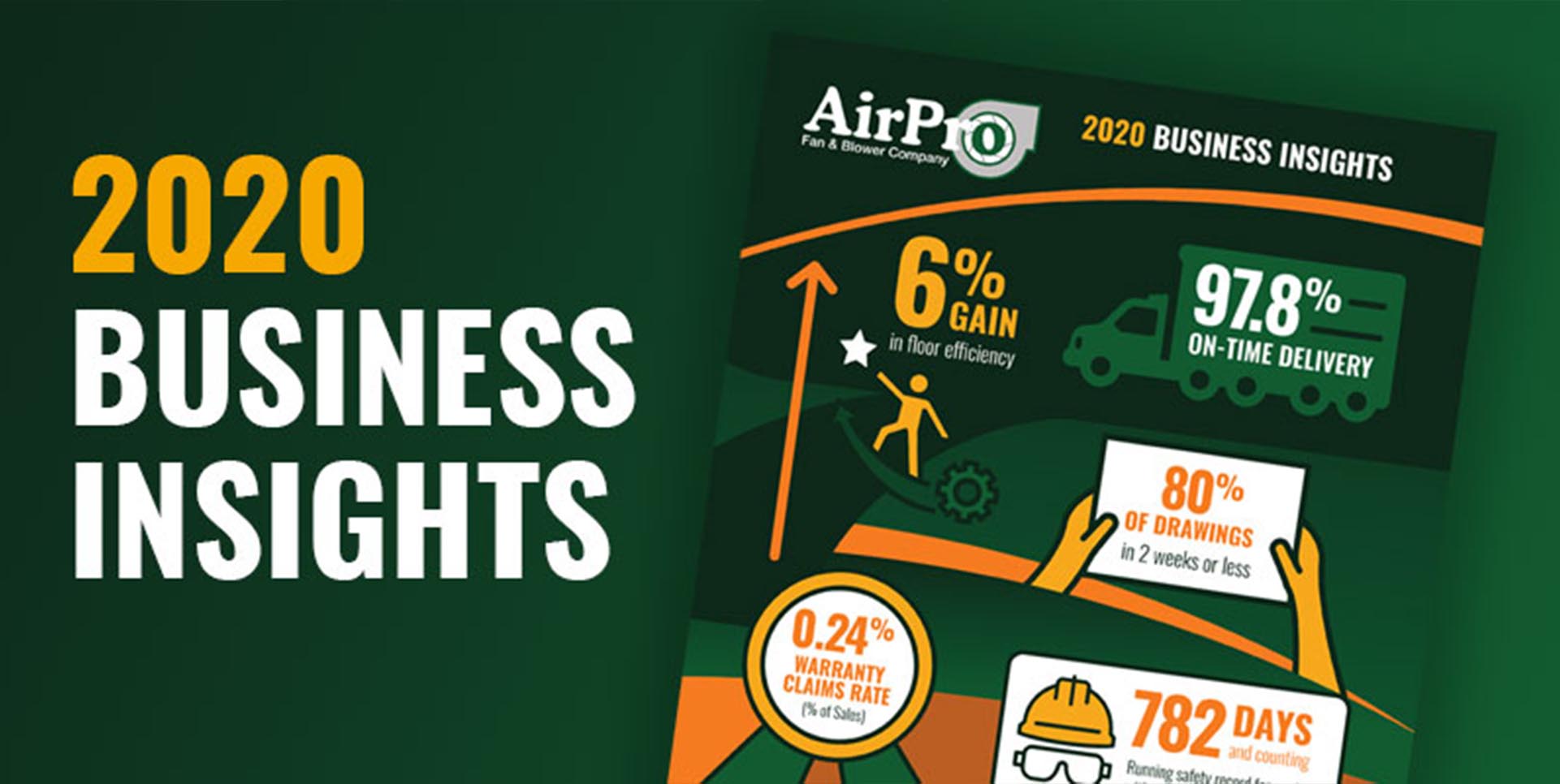

At the turn of each year, we take the time to look back at what we accomplished in the previous year. That’s an important exercise for an organization dedicated to continuous improvement based on serving the customer with absolute reliability and quality. From manufacturing efficiency to sales growth, year-over-year progress and momentum are key to a strong and sustainable business.