In this video viewers have an opportunity to visit AirPro’s Performance Testing Lab where shop technicians and engineers test our fan product lines before release. The lab includes two sections, the Chamber Room and the Sound Room.

Custom

Fan Wheels: The Basics

One of the coolest things about building fans is understanding industrial fan applications. At AirPro, we build all types of fan wheels depending on customer needs. So why one fan type over another? It all has to do with application.

Reasons for Measuring a Fan

Generally, there are two reasons to measure a centrifugal fan – the user wants to retrofit the fan (or parts) or replace it with a new fan. In either case, accurate measurements are critical to replicating the system currently in place, especially if no drawing is available. If possible, separate or isolate the fan from the system to access key measurement points. If duct work on the inlet or outlet is in the way, this could impact measurement accuracy.

Custom Fan Colors for Exterior Paint

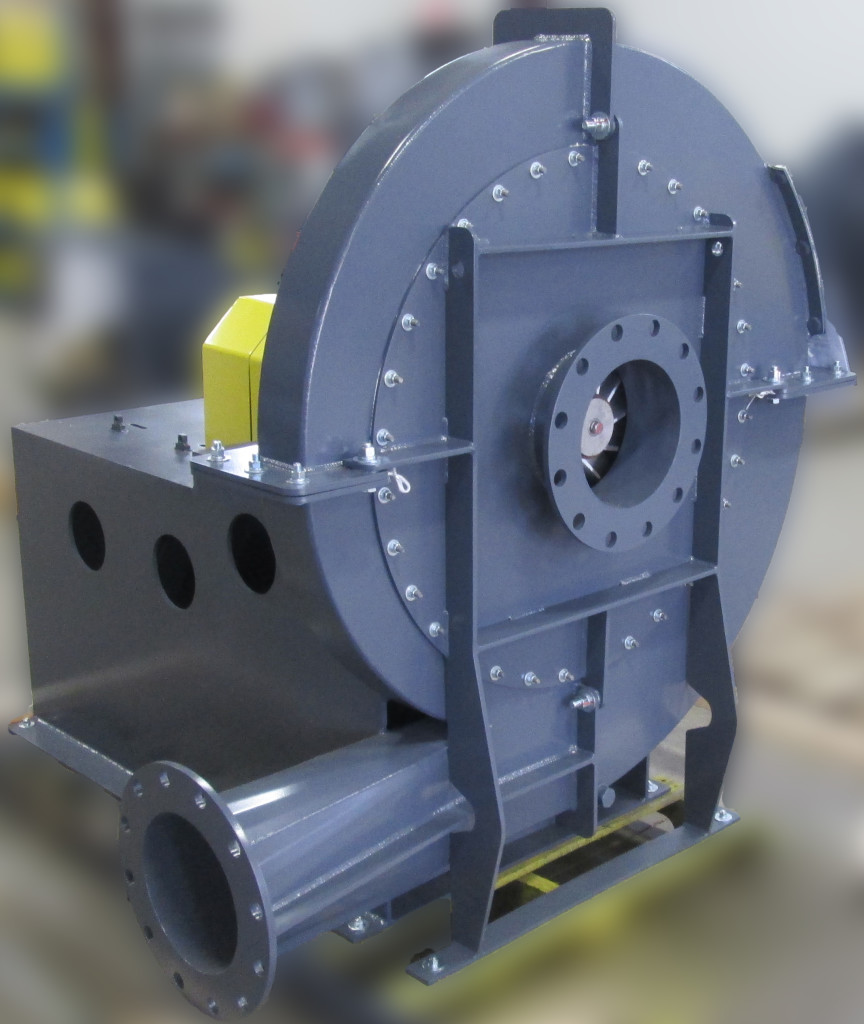

Custom fan colors allow your centrifugal fan to stand out or blend in with the surrounding industrial application from an external aesthetic perspective.

A European company recently contracted AirPro to build an induced draft (ID) fan for their US-based project. The project had several custom requirements including a very short lead time within a fixed budget. Successful execution required a dedicated AirPro project team.

Built for a large chemical processing plant, this impressive blower was specified through the end-user’s consulting engineer. Some of the features included API specs, 304 SS, dedicated project team for completely custom design, and field installation inspection & balance.

The following exhaust fan was installed on the dust collection system for a US producer of pelletized sulfate. Pelletized sulfate is a soil amendment used to improve soil properties in corn, soybean, and other crops.

Story: The following high temperature fan was built for a power company in Colorado. Several years ago, the customer had purchased a Selective Catalytic Reduction (SCR) system with fans provided by a competitor. What followed was a continuous string of unresolved bearing failures that resulted in unreliable performance and unacceptable maintenance costs. Finally, AirPro was called in to review the application and offer a solution.

The following plug fan was rebuilt for a US steel company that heat treats customer supplied castings for automotive companies. After this user’s fan from another fan supplier failed, AirPro was asked to produce a dimensional & functional match. AirPro’s engineers reverse engineered the “model fan” and produced a “match.”

Our customer requested an expedited delivery on Monday because they needed the fan ASAP. Sales promised a 5-day delivery. Engineering provided an accurate, customer-specific design. In two days Manufacturing built a rugged, industrial duty fan with custom dimensions. By Friday, 4 days following confirmation of expedited ship date, the fan had been balanced, painted, assembled, trimmed, and shipped.