Not long ago we updated all of the applications pages on our website. They’re full of information, including related case studies and products. Over the coming months, we’ll be providing overviews of some of our most common applications, starting with material handling systems.

Material Handling Equipment

Whether the material handling system is moving air laden with particles as a byproduct of the manufacturing operations (like sand, sawdust, or metal scrap), or moving the materials being produced (like pet food, wood chips, or plastic pellets), the airstream can be a challenge for the material handling equipment. This includes trim – also known as edge trim – handling systems. Trim is the excess material cut off in a production process and includes things like plastic, paper, packaging, and die-cut metal.

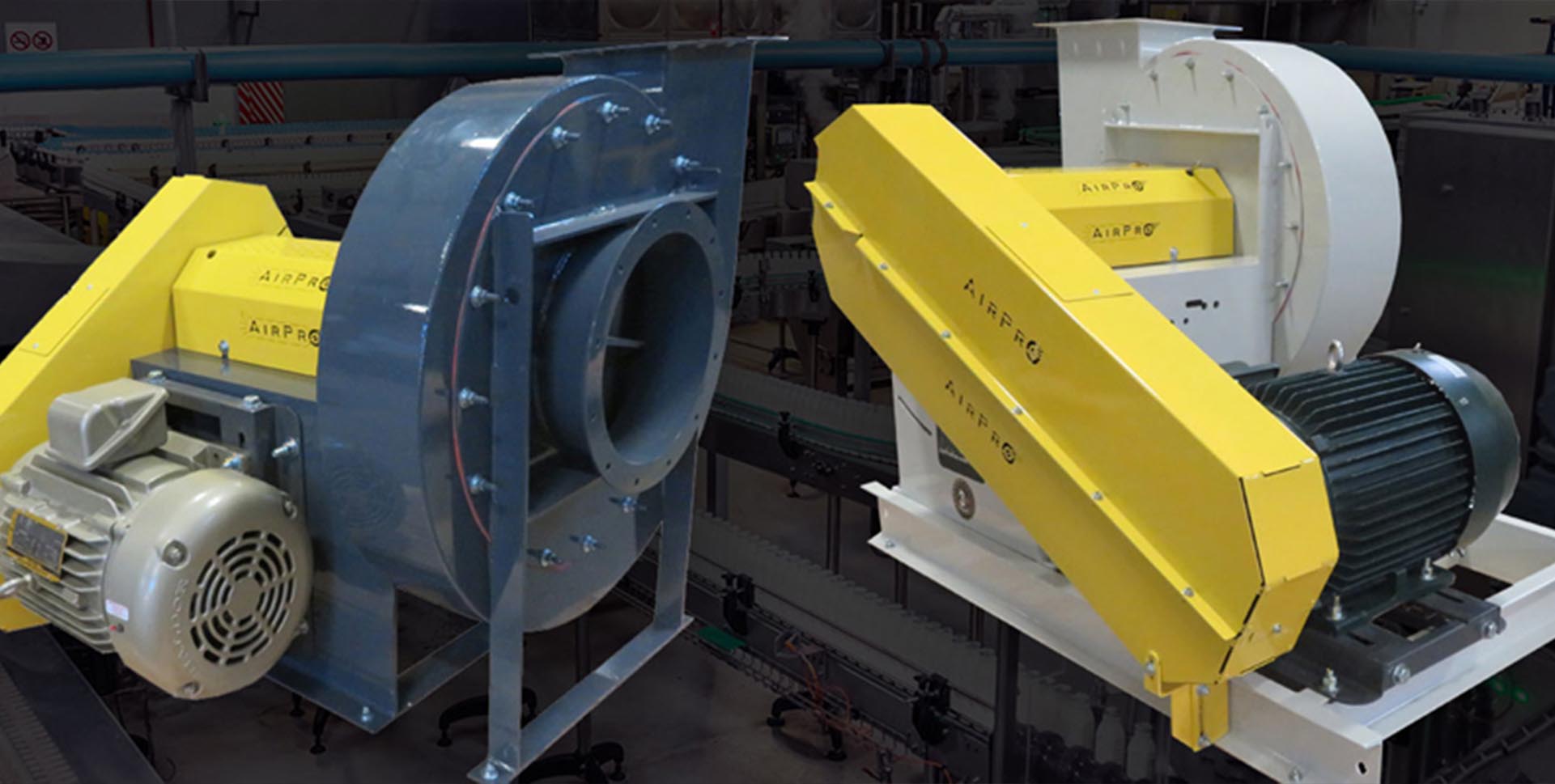

In general, remember that material handling systems require heavy-duty and abrasion-resistant fans to stand up to the wear and tear of the materials. The fans recommended most often for these systems are high-pressure blowers and open radial industrial exhaust, or paddle wheel models.

Design Factors for Material Handling Equipment

The type of particulate or objects in the system help determines what kind of fan to use and what kind of specifications the material handling system requires. The nuances depend on your application and are outlined on the specific application pages. We’ve outlined the top material handling system considerations below.

Keep Material and Air Moving

Air, gas and material conveyance is the primary job of the fan, and it includes making sure things don’t get stuck in the process. How you do that depends on your fan curve and what you’re moving. To get it right, you’ll need to know the bulk density, volume, and characteristics of the materials in the process, along with system volume/pressure and horsepower requirements.

Minimize Damage from Abrasive Material

Abrasive and/or corrosive material can wreak havoc as it moves through the system, so the construction of your material handling equipment is very important. You’ll want to consider heavy-duty construction with abrasion-resistant materials like AR400 Carbon Steel, Teflon, or even Stainless Steel if you’re process needs to be food grade. You can count on some damage though, so be sure to follow a regular and comprehensive monitoring and maintenance schedule.

Resist Particle Build Up and Clogging

When materials are sticky or tacky, they can literally gunk up your system. The shape and inclination of your fan blades and the materials of construction (like Teflon) can make a huge difference in your ability to maintain and operate your fan efficiently. That’s one reason we tend to use open radial designs rather than shrouded designs for material handling systems. It helps avoid materials getting trapped inside.

Prevent Snags in Trim Handling Applications

In trim handling applications, the welds become even more important than usual, often specifying a “no-snag” finish with completely smooth welds to keep material from getting hung up on snag spots inside the fan.

Custom Design Makes the Difference in Material Handling Systems

We talk to our reps serving original equipment manufacturer (OEM) customers in the field with trim handling and material handling equipment. Long-time reps like Adam Conley at Systech Design and Mike Krayer at 3B Air Systems tell us that the level and degree of customization in AirPro’s designs is a big reason that our fans are so often the right solution for material handling systems.

“Not everyone can live up to heavy-duty 24×7,” according to Conley. Krayer added, “AirPro’s custom approach to fan design and construction provides perfectly tailored solutions for each application as opposed to simply providing ‘off-the-shelf’ products.”

Content Related to Material Handling

Here are related posts and case studies that might be of interest as you think about your application.

- Material Handling Application

- Trim Handling Application

- Emergency PPE Production

- Material Handling Fan

- Ethanol Plant Milling Operations

- Material Handling Fans, Paper Trim

We’ll be highlighting several more of our applications over the course of the year. Keep your eye on the All Things Fans blog and sign up for our newsletter to stayup to date. We also welcome comments and questions via our LinkedIn Page.

Contact us for a connection with your local rep or to schedule an appointment with an application engineer, and you can always Request a Quote if you’re ready to roll.